Overview: The technology of oxidized pellets in China has developed rapidly, and more than 10 oxidized pellet plants have been built to provide high-quality pellet ore for blast furnace ironmaking, which is the future development direction of the steel industry. Constructing a large-scale oxidized pellet plant with a relatively small footprint can effectively reduce the investment per unit product, significantly reduce the energy consumption per unit product, and thus lower product costs. Due to the high level of equipment and technology in oxidized pell...

Tel: +86-513-88755311 88755027

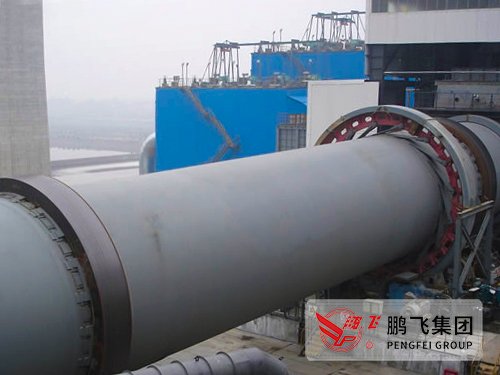

The rotary kiln used for ball production in the steel industry mainly consists of a rotary part, a supporting part, a transmission device, a kiln head cover, kiln head and tail seals, and a combustion device. The kiln mouth guard and kiln tail return spoon are cast in blocks, which are easy to install and have high heat resistance, corrosion resistance, and wear resistance. The cold air sleeve at the kiln head is filled with cooling air, which can evenly cool the kiln head cylinder and kiln mouth guard, making it safer and more reliable. The kiln hood adopts a large volume method and a double opening kiln door structure, making the airflow more stable. The sealing of the kiln head and tail adopts a dual sealing form of radial friction labyrinth and fish scale, with a simple structure and easy maintenance. The combustion device adopts a swirl type four channel coal powder burner with fuel injection ignition device.

| Product Name | Specification | Capacity (t/h) | Power (KW) |

|---|---|---|---|

| Rotary dryer | Φ 1.8× 14m | 30-40 | 22 |

| Rotary dryer | Φ 2× 14m | 40-60 | 22 |

| Rotary dryer | Φ 2.2× 12m | 50-55 | 55 |

| Rotary dryer | Φ 2.2× 16m | 40-45 | 75 |

| Rotary dryer | Φ 2.4× 18m | 45-60 | 95 |

| Rotary dryer | Φ 3× 20m | 160 | 220 |

| Rotary dryer | Φ 3.6× 24m | 150 | 250 |

| Rotary dryer | Φ 4.2× 25m | 250 | 315 |

| Disc ball making machine | Φ 3.6m | 18-20 | 22 |

| Disc ball making machine | Φ 4.2m | 28-33 | 55 |

| Disc ball making machine | Φ 4.5m | 35-45 | 75 |

| Disc ball making machine | Φ 5.5m | 40-60 | 110 |

| Disc ball making machine | Φ 6m | 65-70 | 110 |

| Chain grate heating machine | 1.6× 24m | 100000 to 200000 tons/year | 15 |

| Chain grate heating machine | 2.4× 24m | 300000 tons/year | 11 |

| Chain grate heating machine | 2.8× 36m | 400000 to 600000 tons/year | 18.5 |

| Chain grate heating machine | 2.8× 42m | 400000 to 600000 tons/year | 18.5 |

| Rotary kiln | Φ 2.2× 18m | 10-12 | 45 |

| Rotary kiln | Φ 2.5× 20m | 18-25 | 30 |

| Rotary kiln | Φ 2.8× 22m | 30-34 | 90 |

| Rotary kiln | Φ 3× 28m | 40 | 90 |

| Rotary kiln | Φ 3.5× 30m | 50 | 220 |

| Rotary kiln | Φ 4× 30m | 90 | 190 |

| Rotary kiln | Φ 4.7× 35m | 140-180 | 315 |

| Rotary kiln | Φ 5× 35m | 165-202 | 315 |

| Rotary kiln | Φ 6.1× 40m | 226-335 | 315 |

| Oxidized pellet ring cooler | 20m 2 | 40 | 7.5× 2 |

| Oxidized pellet ring cooler | 30m 2 | 40-60 | 11× 2 |

| Oxidized pellet ring cooler | 40m 2 | 90 | 15× 2 |

| Oxidized pellet ring cooler | 50m 2 | 112 | 15× 2 |

| Oxidized pellet ring cooler | 69m 2 | 130-160 | 11× 2 |

| Oxidized pellet ring cooler | 121m 2 | 270-304 | 15× 2 |

| Oxidized pellet ring cooler | 128m 2 | 280-315 | 18.5× 2 |

| Burned ball ball ring cooler | 140m 2 | 302 | 11× 2 |